The first part I decided to focus on was the claw mechanism. After some quick research I found a claw that I could buy that was servo operated and looked really cool! However, I quickly realised that this would not be a good choice as it could only open to just under 4". Seeing as most the robots are 4" wide, it would mean that the claw would struggle to pick any of them up. However, I liked the metallic look of it and the fact it was controlled by a servo and decided that any claw I had needed to be metal (plastic would be easily broken by spinners) and controlled by a servo.

The next one I found looked much better, had an opening width of 4.20" and was controlled by a servo. However, it was made of plastic. As mentioned above, I need the gripper part to be made of metal as plastic is very easily broken by spinner robots. Seeing as it was such a simple mechanism, I decided that I would have a go at making one myself. This would be cheaper and the final product would be more suited to my need.

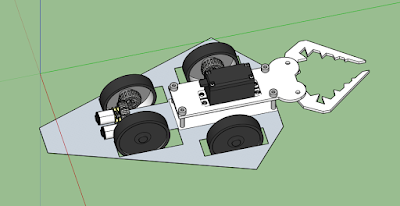

I am somewhat of a novice when it comes to CAD, having only really used a tiny bit of SolidWorks before for a GCSE project a few years ago. With the software installed on the university computers I had two choices, AutoCAD or Google Sketchup. I started of by having a bit of a play with AutoCAD, knowing that it is a very useful and powerful tool in the right hands. However, in my hands I found it difficult to make even the simplest of shapes and I could see myself spending a very long time learning how to use the package. I decided that, because all my shapes are fairly simple, to use Google Sketchup, safe in the knowledge that if anything I needed to do that required a more complex tool I could export from Sketchup to AutoCAD.

After a while of playing about on Sketchup, a fair few mistakes and start overs, I had my first claw design. This, I hoped, would work just like the above claw but I now had the ability to make it out of whatever material I so desired. I chose at first to print it out on the laser cutter in MDF to check the mechanism was working properly.

This being my first time using a laser cutter it took a couple of attempts to get it right (my first attempt ended up with a miniature claw!) but eventually I had it printed out fine. I assembled it (as shown below) and surprisingly, everything worked fine! The claw now opens to about 5.2" and can now be made out of whatever material I want.

.jpg)