Motors

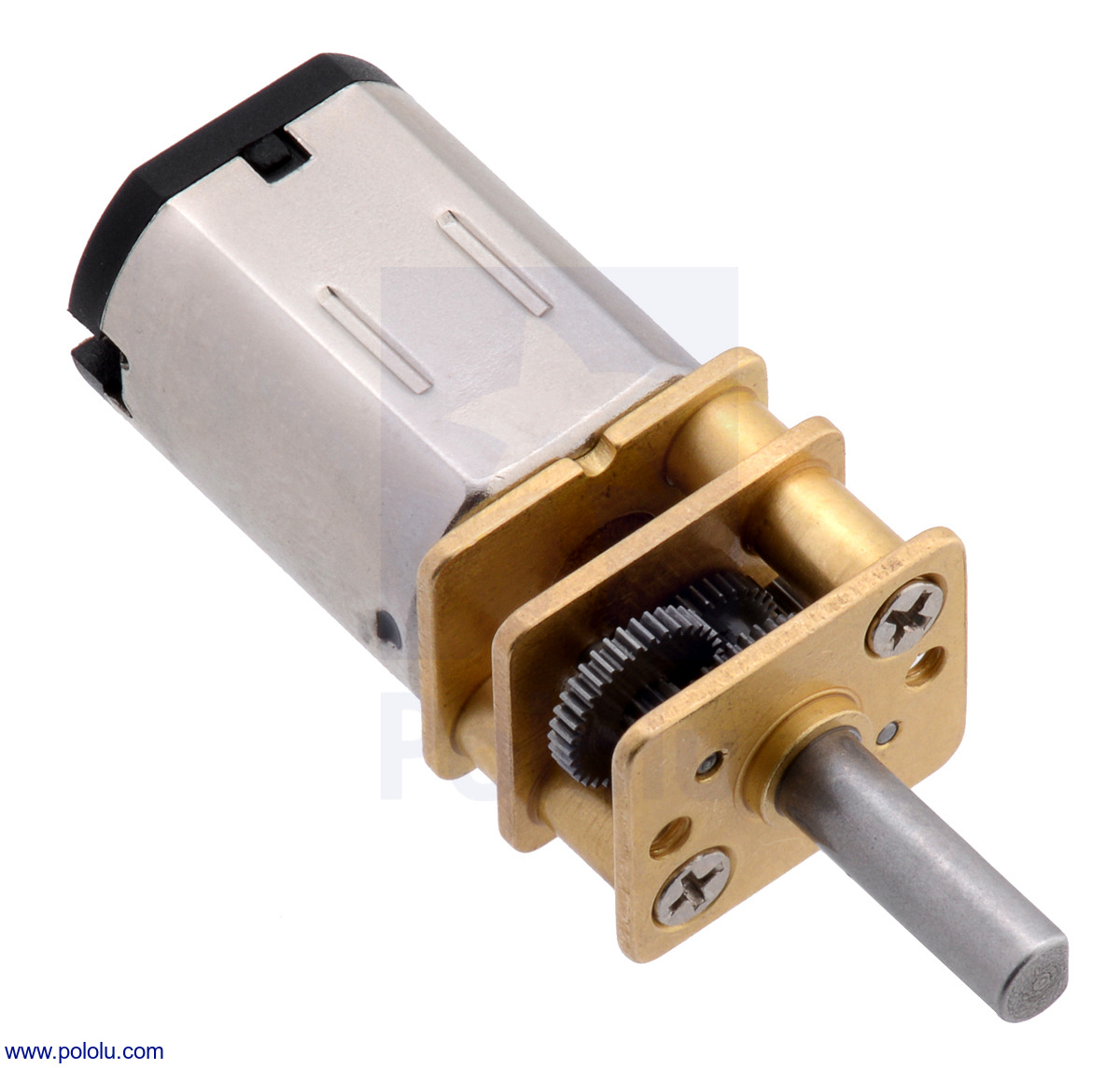

MotorsI have ordered 4 of these micrometal gearmotors. I have chosen the gear ratio to be 100:1. This is slightly slower than most other antweights but has much more torque (320rpm with no load and 2.2kg-cm at stall). This is what is needed for a house robot. Using the specs given, this gear ratio would give a speed of about 2mph with a wheel size ratio on 1".

I also got a standard motor mount for each motor.

Wheels were a surprisingly tricky part to find. I needed four small and grippy wheels. I started looking at the pololu wheels but found they were often too large. Eventually I stumbled across lego wheels. I seemed to be able to find the correct size of wheels but I had no way of telling how grippy they were from the photos. Eventually I took the plunge and ordered 4 wheels intended for a crane kit from eBay. They had a 60mm diameter and a 20mm width.

Battery

I needed a large battery, much larger than any of the other antweights. This is because, not only does it have more "stuff," it also has to fight in every single round of the robot wars. A quick bit of research found that the best type of batteries to use would be the lithium polymer (Lipoly) type of battery. These batteries have a very high capacity to weight ratio and are the go to battery for RC enthusiasts. The one I chose, here, has a very large capacity but still fairly small so should be able to fit in well inside the robot.

Servo

For the servo used to control the claw, it was important that I chose a servo with a very high torque. This is so that it could easily pick up other bots. There is also no need for it to be super past either. At first I started looked at retract servos. These are servos traditionally used for landing gear on RC aircraft so they can only hold two positions which are 180 degrees apart. Because of this it is possible to make them with lots and lots of torque. However, if I were to use a retract servo it would mean that I would have to design my mechanism perfectly with no room for error and also it could only be open and close, with no position in the middle. With that in mind I had to find just a normal, but high torque servo.

Eventually I found a good servo that gave me 11kg-cm. This is much higher than any others at this price (just under £10) as often to get a really high torque servo you can pay upwards of £30-40.

.jpg)

No comments:

Post a Comment